A report on the SER Convention

By Clinton Smoke

Several MNCMRC club members attended this year’s SER Convention in Cartersville, GA. They were treated to good southern hospitality and an extensive array of activities. The convention included three prototype tours, 14 home layout tours, 24 clinics, a banquet and auction. All of the activities were well worth the time.The convention was held at the Komatsu Training Center in Cartersville, Georgia, a beautiful, functional facility that is normally used for training Komatsu employees and customers. The company kindly turned their facility over to the members of the Piedmont Division of NMRA for the weekend. The clinics, contests and Train Show were held at the center.

On Saturday morning we had the choice of two prototype tours: a power plant and rail-car manufacturing facility. Both looked interesting. The Bowen Plant of Georgia Power is one of the largest coal-fired power facilities in the county; they consume a train of coal daily! The other tour was to Trinity Rail Group, one of the nation’s largest rail-car manufacturing facilities. Both tours looked inviting, but, unfortunately, one can only be in one place at a time. I took the Trinity Tour.

Trinity Industries, Inc. is one of the nation’s leading diversified industrial holding companies with a subsidiary group that provides a variety of high volume, repetitive products and services for the transportation, industrial, construction and energy sectors of the marketplace. Trinity’s subsidiary group operates in five distinct business groups: The Trinity Rail Group, Trinity Railcar Leasing and Management Services Group, Inland Barge Group, Construction Products Group and Energy Incorporated in 1933, Trinity Industries, Inc. began as a Dallas-based manufacturer of storage tanks, truck tanks and transports for the LPG industry. In the mid-1960's, TrinityRail capitalized on its manufacturing expertise to begin producing tanks for tank-car manufacturers. This evolved into finished tank cars. As demand for railcars grew in the late 1980's and 1990's, TrinityRail emerged as a leading provider of rail equipment through internal expansion and a series of key acquisitions, first acquiring the railcar-design and manufacturing assets of Pullman Standard, followed by Greenville Steel Car, and Ortner Freight Car. TrinityRail entered the railcar-components market through the acquisition of Standard Forged Products, the leading industry supplier of railcar axles. In 1998, they expanded into the foundry business by acquiring McConway & Torley, the leading manufacturer of railcar couplers.

Today, Trinity's rail manufacturing businesses include the largest volume producers of freight and tank railcars in North America. Trinity North American Freight Car, Inc. manufactures a full line of railcars, including box cars, gondolas, intermodal cars, covered and open hoppers and auto carriers. The latter two are manufactured in Cartersville, Georgia.

The Cartersville facility has about 1000 employees. They build auto carriers and two kinds of hoppers. The hoppers include a conventional four-bay hopper and a not-so-conventional rapid-discharge hopper used primarily in colder regions. These hoppers have two pairs of large doors that run parallel to the center sill, allowing coal to be dumped, even if partially frozen. The auto carriers are pretty standard.

On the following page are pictures taken at the facility. Starting in the upper left, and continuing down the page, we see auto carriers in the erection shop and in the paint shop. Next we see hoppers in production line and the finished product. Our tour guide explains how the car’s rotary coupler works. Finally we see the Rapid-Discharge car, a Trinity exclusive.

Working in four 10-hour days, the Georgia facility makes about 100 cars a week,. They work as teams, with every aspect of their work measured, including safety. This facility has an accident rate that about 1/5 the industry average. In case you are interested in buying one of their products, you can pick up a nice hopper car for about $80,000, not a bad price as you can expect to get about 40 years of service from the car.

The convention concluded with the traditional Saturday-evening banquet, this time held out doors, at the historic depot, next to the CSX tracks in Cartersville. The weather was perfect, and the trains were numerous. During my 4-hour visit, I saw 9 trains pass, all long trains with mixed freight, auto carriers, and hoppers, some no doubt built in Cartersville.

After a great meal, our superintendent was introduced. Fred Coleman invitingly talked about next year’s SER Convention and the many rail-related, and some not-so-rail related attractions here. Following his presentation, the contest winners were named. Our division did quite well with three winners: Robert Bell won two special Regional Awards with his scratch-built Bea Tardee, shown on page 1. Ben Bartlett received honors for his scratch built Erie Railroad station, scoring 114 (of a possible 125) points. Ben’s wife, Jan Bartlett, won First Place in the Art and Crafts competition with a beautiful sweater. Congratulations to all!

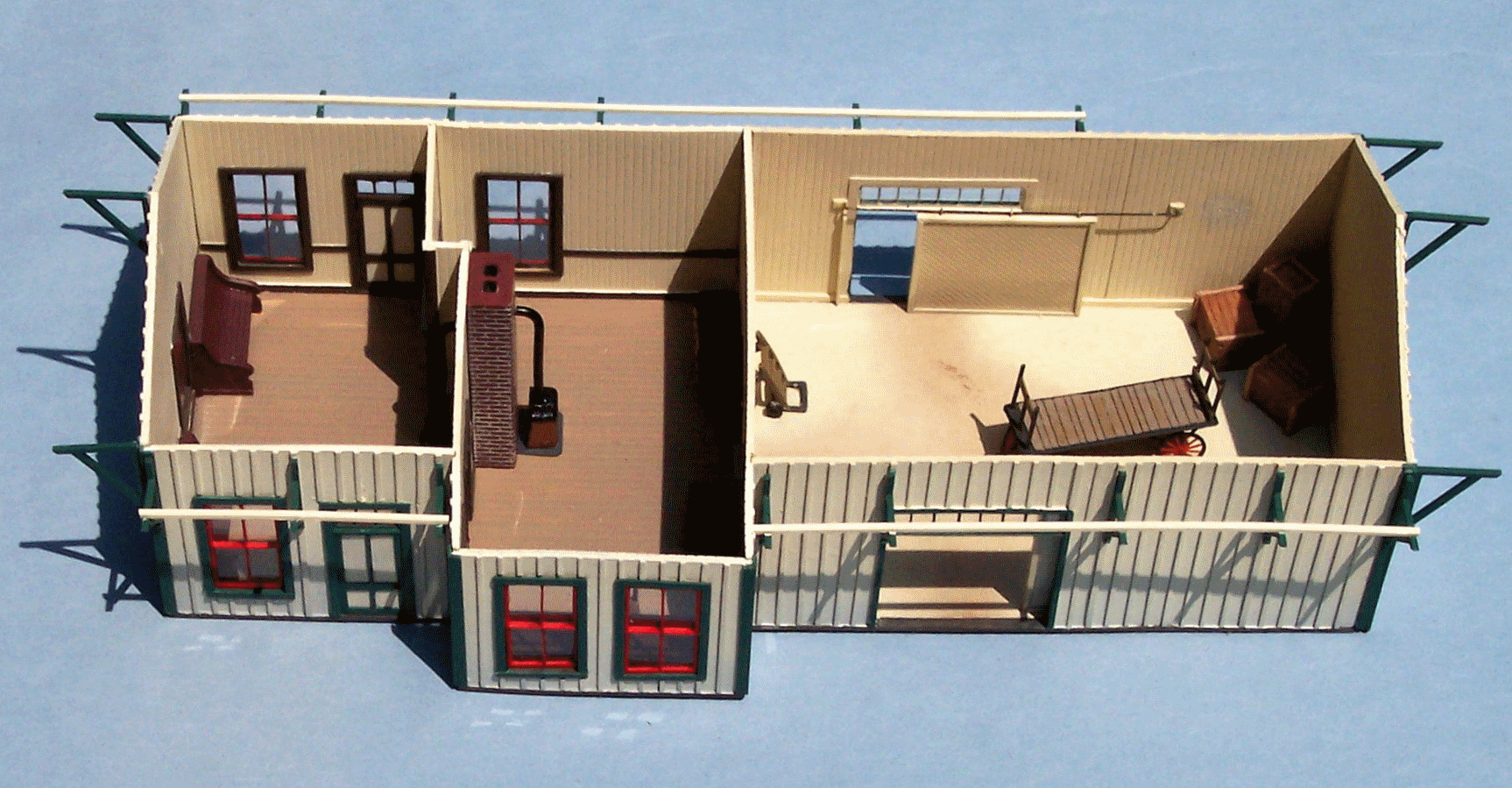

Ben Bartlett’s scratch-built HO scale Erie Railroad Station at Akron, Indiana

Ben Bartlett’s scratch-built HO scale Erie Railroad Station at Akron, Indiana

The convention’s featured speaker was MMR Leslie Eaton of Houston, Texas. She shared some interesting and humorous experiences, starting with her early interests in model railroading, “playing with trains” as she called it, with her dad. She challenged the members present to work on becoming Master Model Railroaders, and to help market the hobby. She suggested that we should occasionally open our layouts to our friends and neighbors, just as we do to fellow model railroaders, and let others see and enjoy what our hobby is all about. She does this on a regular basis and has recruited several to the hobby as a result. There are more pictures of this year’s SER Convention on the next page.